Project Overview

The Fingerboards Project

The Fingerboards Critical Minerals Project, delivered by Gippsland Critical Minerals, will responsibly develop high-grade deposits of rare-earths and critical minerals listed on the Australian Government’s Critical Minerals List.

Overview

The Fingerboards Project is located within the Glenaladale deposit in East Gippsland, Victoria, approximately 270 kilometres east of Melbourne.

Once operational, the Fingerboards Project will produce around 280,000 tonnes per year of Heavy Mineral Concentrate (HMC) containing:

- 14,000 tonnes per year of rare earth minerals (xenotime and monazite), which include about 200 tonnes of heavy rare earth oxides (dysprosium and terbium) and 1,800 tonnes of light rare earth oxides (neodymium and praseodymium). These elements are essential in high-performance magnets used in electric vehicles, wind turbines and defence applications.

- 75,000 tonnes per year of zircon, used in ceramics, electronics and advanced manufacturing.

- 150,000 tonnes per year of titanium minerals (ilmenite, leucoxene and rutile), used to produce pigments and titanium metal.

Analysis by Appian Capital indicates that, if in production today, Fingerboards would contribute 40–50% of ex-China production of the world’s dysprosium and terbium oxide supply, underscoring its importance in securing diversified global supply chains.

Together, these products contribute to industries that power the clean-energy transition and support advanced manufacturing in Australia and globally.

A new project for East Gippsland

The 2025 Fingerboards Project is smaller in scope, size, scale and environmental impact than the 2021 proposed project. It provides greater certainty to the community and Government on key matters relating to:

- Water requirements and water sourcing

- Management of tailings

- Soils and rehabilitation

- Water run-off and quality of water impact

- Impact of mining on native vegetation

- Dust and air quality, including a commitment to real-time and transparent monitoring of the key concern of dust and air quality.

A new Feasibility Study is underway, based on 7.2 million tonnes per annum (Mtpa) of shallow progressive mining using low-disturbance in-pit dozer push mining units. Ore will be slurry-pumped to an on-site wet concentration plant, using water sourced from multiple groundwater and recycled sources to produce a heavy mineral concentrate (HMC) via traditional gravity separation.

With improved mine design, sustainable water and tailings management, and close collaboration with local community and Traditional Owners, the Fingerboards Project is positioned to become a leading Australian supplier of rare earths, zircon, and titanium, delivering long-term community benefits including water infrastructure, resumption of freight rail services, regional employment and economic benefits for workers transitioning from closing timber and coal industries.

Interactive Map

Explore the project

Through an iterative design process and ongoing community engagement, GCM will deliver a best-practice, environmentally responsible project that provides enduring benefits for East Gippsland, Victoria, and Australia.

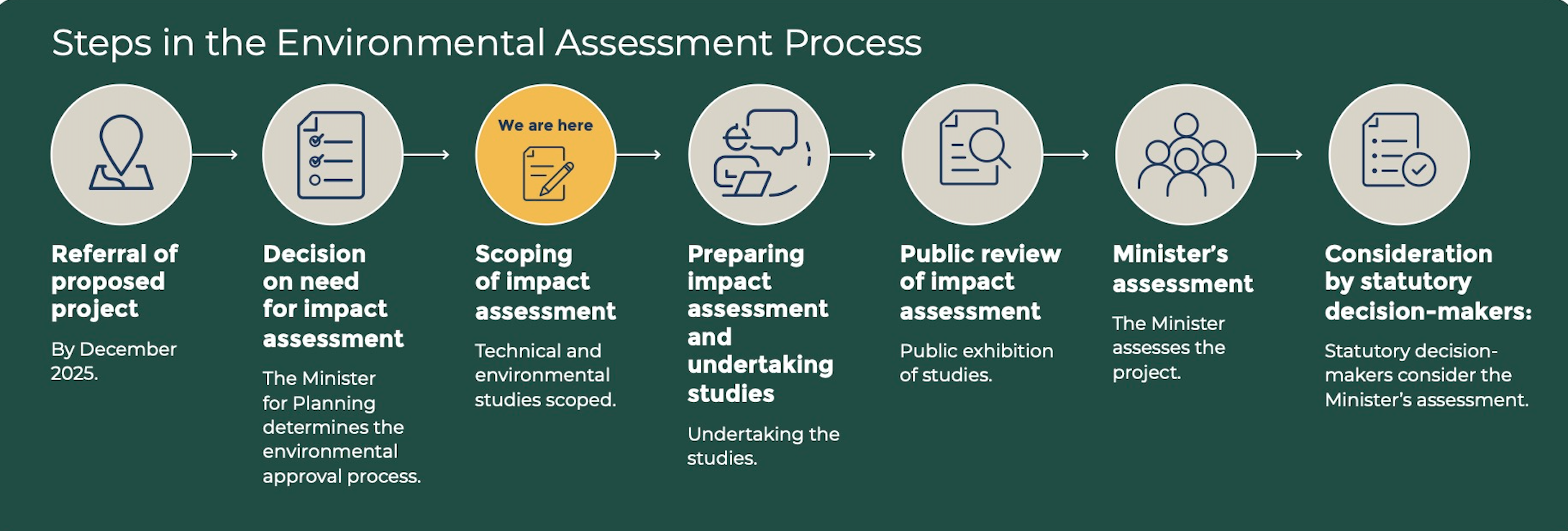

Status: EES RequireD

Victorian Minister for Planning Sonya Kilkenny has determined that the redesigned Fingerboards Project will undertake an Environment Effects Statement (EES).

The Ministers decision recognises that the rescoped project is materially different from the proposal considered in 2021 and warrants new assessment under the Environmental Effects Act 1978.

The Minister’s decision and statement of reasons are available on the Department of Transport and Planning website.

Extensive studies are already underway, available on our monitoring and studies page. If you have any questions or want to learn more, contact us.

Progressive mining

95%

Mineral sand recovery

By mining in stages, and progressively returning unused sands to the site by backfilling and rehabilitating the land.

Environmental mitigation

1.5 Km

Mining exclusion zones

No mining 1.5 kilometres from the Lindenow Valley Horticultural Area or in the Perry, Simpson and Lucas Creek gullies.

Critical minerals

8 Mt

Total production target

GCM aims to extract globally significant amounts of heavy mineral concentrate (HMC) over the life of the project.

Powering clean energy

10 GW

New wind power

Production at Fingerboards could help bring online over 10 GW of new wind power annually, enough to power 5 million homes.

Design Elements

Smaller footprint, new design

Mining

Smaller Footprint, Staged Approach

The redesigned Fingerboards Project has a 27% smaller mining and separation area than the 2021 proposal. A 1.5-kilometre exclusion zone has been established around the Lindenow Valley horticultural area, and no mining will occur in the Perry, Simpson or Lucas Creek gullies.

Processing

Onshore Separation with Reduced Impact

Minerals will be separated on-site using water and gravity, rather than chemicals, to produce a bulk mineral product. Tailings will be managed below ground, eliminating the need for above-ground dams.

Rehabilitation

Rapid Return to Productive Farmland

Rehabilitation is continuous and integrated into mining, with land progressively restored to agricultural use and native vegetation. Voids will be filled within 12 months.

Water

New Water Strategy provides greater certainty and security

Power

Energy-Efficient Processing Technologies

The Fingerboards Project will utilise energy-efficient technologies and infrastructure to power operations while exploring renewable integration opportunities.

Transport

Reduced Road Transport Impact

We are committed to a rail-first transport strategy that moves product efficiently while reducing impacts on local communities.

Shared Opportunity

We are invested in East Gippsland

Localised funding

$300m

Investment in the development of the mine, prioritising local suppliers

Labor force

~300+

Full-time equivalent jobs throughout operations

Economic Boost

$90m

Annual economic contribution through operations, wages, and supply chain

Information Sheets

Community documents

We recognise the need to do things differently and have re-scoped development to reduce and mitigate environmental impacts. Every step of the way we will be releasing our plans and activities to the public for scrutiny and engagement.

Frequently asked questions

We understand you have questions. Let us answer them.

How will you prevent dust from affecting nearby farms and communities?

GCM’s project has been redesigned to minimise dust at its source. We understand that people are concerned, especially when it comes to air quality, dust, and the long-term health of their families and rescoping to a smaller project is one of the best ways to reduce environmental impacts, particularly in relation to dust.

Key changes include:

- Increasing the buffer zone to significantly reduce the likelihood of any residual dust reaching Lindenow Valley

- Reducing the scale of the mining by 40%, spread across two mining locations to reduce the dust generated at any one location, at any one time.

- Reducing the size of the mining voids and filling them within 12 months, with land rehabilitation beginning immediately after filling.

- Introducing a new method of mining called ‘in pit dozer push’ that will reduce dust generated from overburden removal and from on-surface trucks.

We are also reducing the risk of airborne dust travelling as a result of wind by:

- Establishing storage sheds for the bulk concentrate

- Increasing the use of dust suppressant measures, which will be tested as part of the demonstration pit trials

- Using a changed rehabilitation strategy to accelerate ground cover establishment and the return of the land to agricultural use and native grass.

We expect these measures will dramatically reduce dust, and quantifying the impact of these proposed mitigation measures is now the subject of detailed assessments and studies. This includes plans for a demonstration pit in early 2026 to ensure our dust modelling and rehabilitation strategy is tested in situ.

GCM expects to be able to quantify the reduction in the amount of dust generated and any dust impacts as part of these studies, which will be released as part of the environmental approvals process.

GCM also expects that air quality monitoring, which will be made available to the public and regular independent testing by a trusted third party and regulatory oversight, will form part of the final rescoped project.

What measures are in place to protect local water supplies and waterways?

Our water management plan focuses on responsible sourcing, efficient recycling, and strict quality controls. We’re designing the project to capture and treat all site water before any controlled release, with monitoring upstream and downstream of operations. By implementing progressive rehabilitation and erosion controls, we’ll protect waterway health throughout mining and beyond. We’re also exploring opportunities to enhance long-term water security for both the project and local communities.

Will radiation from mineral sands pose health risks to workers or residents?

The naturally occurring radiation in mineral sands is low-level and carefully managed.

Radiation at high levels occurs during a type of mineral sands processing that is not going to occur at Fingerboards.

It is only during final processing, in Western Australia and the Northern Territory, almost 4,000km from East Gippsland, that any radiation from NORM would be concentrated enough to be classified as Radioactive Material (Class 7). In Western Australia and the Northern Territory, specific measures are in place to manage these outcomes at these processing locations, which are subject to strict regulatory oversight from the Australian Radiation Protection and Nuclear Safety Agency (ARPANSA).

To provide independent monitoring against the baseline levels at Fingerboards, the Victorian Department of Health has installed its own monitoring stations across the site.

How long will it take for mined land to return to productive agricultural use?

With smaller voids, land will be filled within 12 months, and rehabilitation will begin immediately across the site. This approach means land returns to productivity much faster than traditional mining. Typically, areas can return to agricultural use within 2-3 years after mining. We’re demonstrating this process with our rehabilitation trial, showing how quickly land can recover when proper soil reconstruction and revegetation techniques are applied.

What will happen to local wildlife and vegetation during mining operations?

GCM is conducting detailed ecological surveys to identify important habitats and species. However, as a first step to improve on the design of the previous project and reduce impacts, GCM has rescoped to preserve key wildlife corridors and environmental features, particularly through our gully areas. Work on our ecological studies includes baseline monitoring has already begun and the process is being lead by GHD. You can read the scope of those studies here.

We relocate wildlife from active mining areas and restore native vegetation through our nursery program, which cultivates local species for rehabilitation. Our goal is to enhance biodiversity value over time, creating more diverse and resilient ecosystems than currently exist in some areas.

How will climate change impacts be considered in your environmental planning?

Climate modelling is a key component of our environmental planning. We’re assessing how changing rainfall patterns, temperature, and extreme weather events could affect our operations and rehabilitation success. Our water management systems are designed with capacity to handle increased rainfall intensity, while our revegetation programs select species resilient to predicted future conditions. We’re also exploring opportunities to incorporate renewable energy into our operations to reduce our carbon footprint. We have installed a second weather monitoring station as part of our baseline monitoring work and real time data from that station will soon be available online.